UNDERGROUND

DRILL JUMBO

SIMULATOR

PC-Based Equipment Simulators: Cost-Effective Hands-On Training Tools

Drill Jumbo Personal Simulator puts trainees at the controls of a modern twin boom Drill Jumbo in an underground mining tunnel (drift).

Training efficiency is delivered through a modular Instructional Design that teaches real skills for productive and safe equipment operations in the field.

You can either use your own PC or choose the convenience of our PC bundle with the software already installed, licensed, and ready to go in English or Spanish. You can even change the viewpoint during the simulation at the touch of a button!

UNDERGROUND DRILL JUMBO SIMULATOR

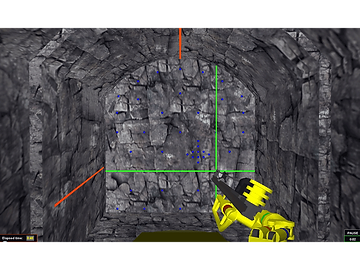

Module 2: Drill Steel Alignment with Laser Lines

The objective of Module 2 is to learn to drill single stope holes using a single boom and grade and back line orientation cues.

Module 3: Dual-boom, Multiple Hole Drilling

The objective of Module 3 is to learn to drill a series of stope holes using two booms and grade and back line orientation cues.

Module 5: Round Drilling

The objective of Module 5 is to learn to drill a a complete round (including stope, contour, and lifter holes) using two booms and grade and back line orientation cues.

Underground Drill Jumbo Software Description

There are six “Simulation Modules” of increasing difficulty. Early Simulation Modules present a single hole to be drilled at a designated position and orientation. Later Simulation Modules require drilling complete rounds and cross-cutting in wider drifts.

Simulation Modules

-

Drill steel alignment with an angled target

-

Drill steel alignment with laser lines

-

Dual-boom, multiple hole drilling

-

Dual-boom, multiple hole drilling 2

-

Round drilling

-

Single boom cross cutting

Key Features

-

Highly realistic simulation graphics and physics

-

6 Simulation Modules of increasing difficulty

-

10 unique Performance Indicators to comprehensively evaluate the simulated work

-

Many kinds of lever-based and joystick-based USB-ready simulator controls and mounting options

-

Functionality to slow down, speed up, or reverse control functions

-

Viewpoints from inside and outside the cabin that can be changed during simulation

Tracking Results

Ten (10) unique key Performance Indicators measure how quickly and how carefully the simulated work is performed. Feedback is diagnostic, instead of just a consolidated pass/fail score. They include execution time, grade deviation, drift collisions and vertical deviation at the collar.

Software Pricing

Please contact us for pricing of a commercial software license for the drill jumbo simulator. Even small accidents due to inexperience can cost thousands of dollars in replacement parts and downtime, far in excess of your investment in this training tool. This priceless investment in the health and productivity of your workers represents an excellent training value and improves operator safety.

Underground Drill Jumbo Simulator Controls

Lever Style Replica Controls

Lever-style Replica Controls reproduce the essential elements of Atlas Copco’s “Direct Control System” (DCS) operator controls, as follows:

-

Four industrial levers

-

One multi-purpose joystick with 8 push-buttons (compatible with many other Simlog products).

Joystick-Style Replica Controls

Joystick Style Replica Controls for Drill Jumbo Personal Simulator feature industrial strength components. There are a total of 8 push-buttons for the thumb, plus a trigger. The USB electronics are built right into the base, so the joystick.

These controls are multi-purpose, so they can be used with Simlog’s Hydraulic Excavator, Bulldozer, Wheel Loader, Mobile Crane, Tower Crane, Forklift, Harvester, Forwarder, and Drill Jumbo Personal Simulators. If you are a Simlog customer, you may be able to re-use the Replica Controls that you already have.

Custom Travel Cases for Replica Controls

For all setups, Simlog's Custom Travel Case makes transportation easy.

Key Features

-

Made-to-measure, with dedicated slots for levers, joysticks, pedals, steering wheel, and table-top mounting brackets

-

Space for a laptop PC, cables, and documentation

-

Pull-out handle, with multiple positions

-

Wheels (casters)

-

Cases are "stackable," for easy transport.

Specifications

-

Overall dimensions: 30 (76cm) x 24 (61cm) x 19 (50cm)

-

Approximate weight: 50 lbs. (23 kg) when empty, up to 100 lbs. (46 kg) when full (depending upon the Replica Controls.)

Joystick-Style OEM Controls

For Simlog’s Drill Jumbo simulation software, we are pleased to offer Joystick-style OEM Controls featuring control handles from the operator controls of Atlas Copco’s “Rig Control System” (RCS).

Note that the simulator controls may be used with Simlog’s table-top mounting brackets.